Airless Lotion Pump: A Deep Dive into Innovation and Benefits

- AmazoniaSilva

- Tháng 12 11, 2024

- Zodiac signs

- 0 Comments

Airless Lotion Pumps have revolutionized the skincare and cosmetics industry, offering a more hygienic and effective way to dispense lotions, creams, and serums. These pumps protect your products from oxidation and contamination, ensuring their longevity and potency.

Understanding the Mechanics of an Airless Lotion Pump

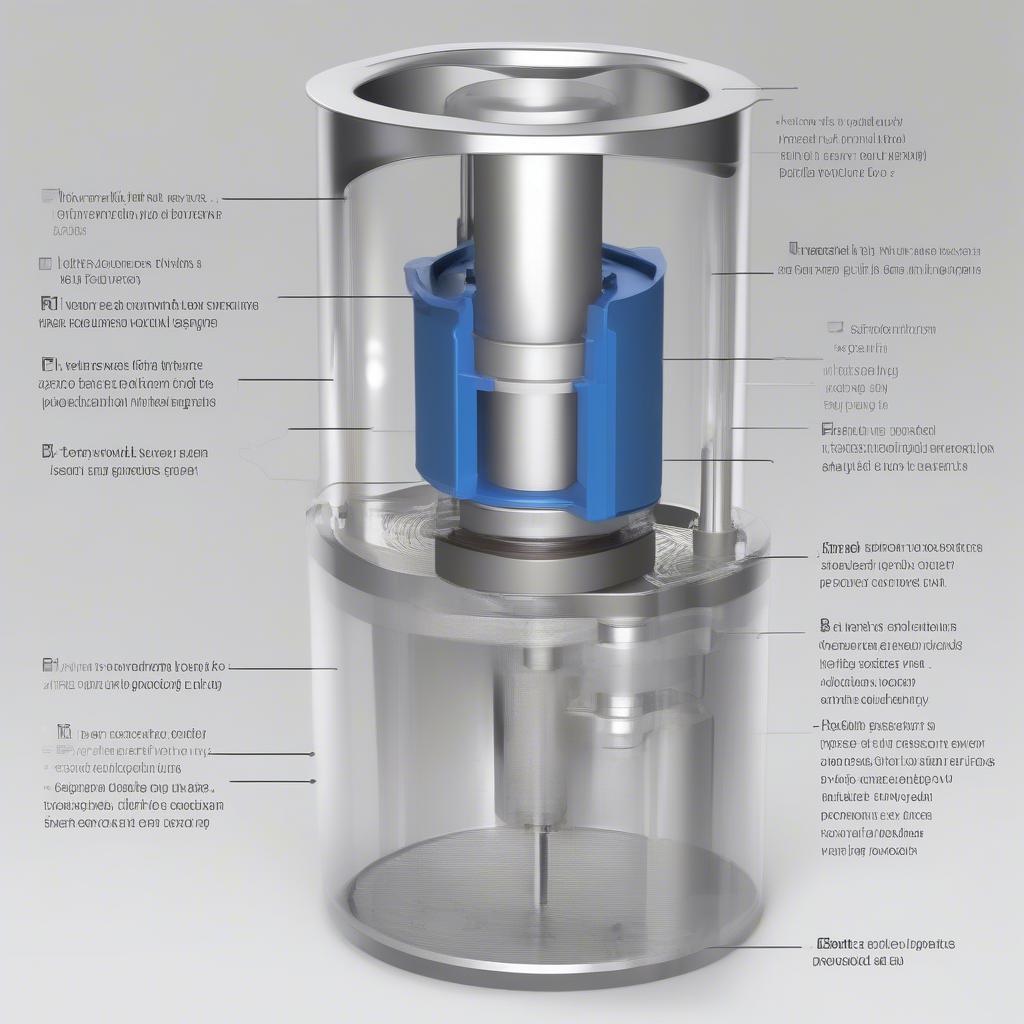

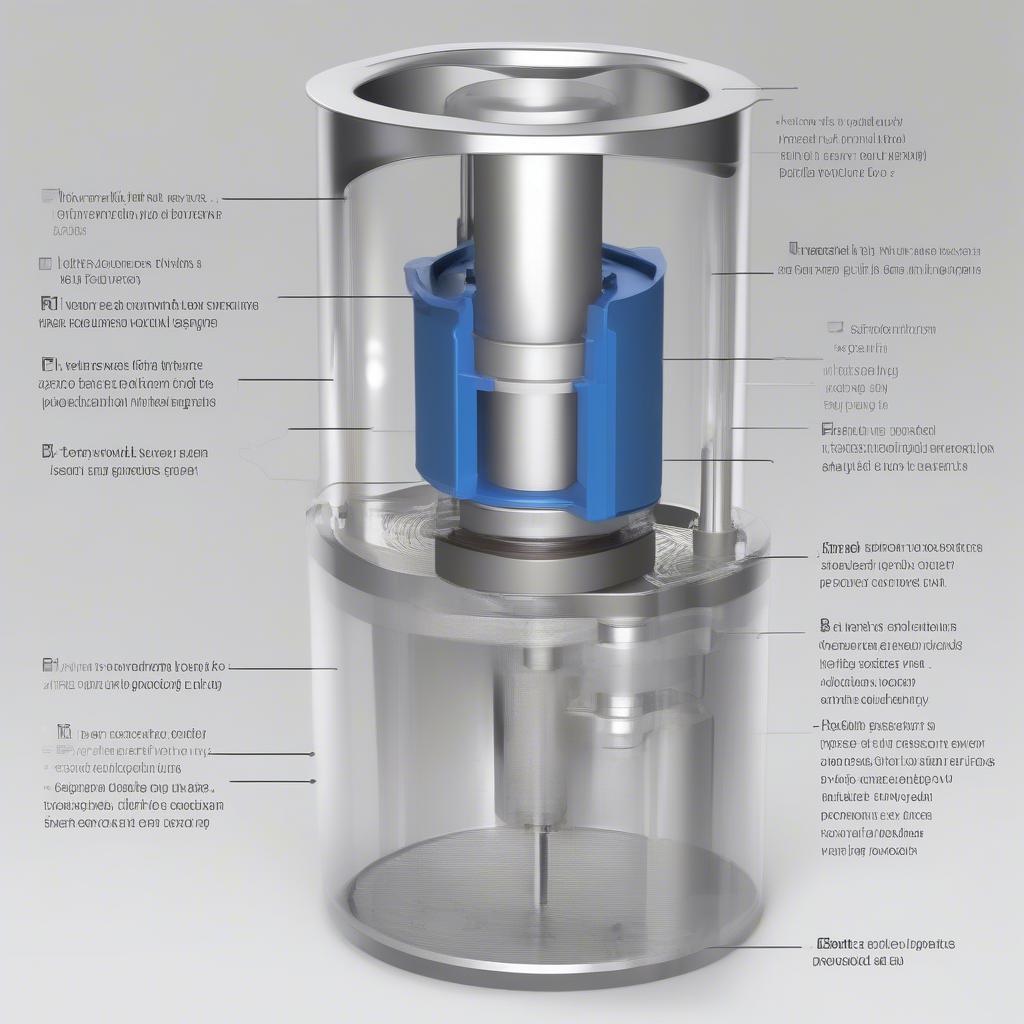

Unlike traditional lotion pumps that rely on a dip tube to draw product upwards, airless lotion pumps utilize a vacuum dispensing system.  Airless Lotion Pump Mechanism Diagram As the pump is pressed, the platform inside rises, pushing the product upwards and out through the nozzle. This vacuum-sealed system prevents air from entering the container, significantly reducing the risk of product oxidation and bacterial growth.

Airless Lotion Pump Mechanism Diagram As the pump is pressed, the platform inside rises, pushing the product upwards and out through the nozzle. This vacuum-sealed system prevents air from entering the container, significantly reducing the risk of product oxidation and bacterial growth.

The Advantages of Using Airless Lotion Pumps

Airless lotion pumps offer numerous benefits for both consumers and manufacturers:

- Preservation of Product Integrity: By eliminating air exposure, these pumps keep products fresher for longer, maintaining their effectiveness and preventing ingredient degradation.

- Hygienic Dispensing: The closed system prevents bacteria and other contaminants from entering the product, making it ideal for sensitive skin.

- Controlled Dosage: Airless pumps deliver a precise amount of product with each pump, minimizing waste and ensuring consistent application.

- 360-Degree Dispensing: Many airless lotion pumps allow for dispensing at any angle, making it easier to access every last drop of product, even when the bottle is nearly empty.

- Enhanced Product Shelf Life: The airtight design can significantly extend the shelf life of products, reducing waste and saving money.

Choosing the Right Airless Lotion Pump

Variety of Airless Lotion Pump Designs Selecting the right airless lotion pump depends on several factors, including product viscosity, container size, and desired aesthetic. Consider the following:

Variety of Airless Lotion Pump Designs Selecting the right airless lotion pump depends on several factors, including product viscosity, container size, and desired aesthetic. Consider the following:

- Product Viscosity: Thicker products require pumps designed for higher viscosity formulations to ensure smooth dispensing.

- Container Size and Shape: The pump should be compatible with the chosen container to ensure a proper fit and function.

- Actuator Design: Choose an actuator that provides the desired dispensing rate and spray pattern.

- Material Compatibility: Ensure the pump materials are compatible with the product formula to avoid any chemical reactions or degradation.

Airless Lotion Pumps and Sustainability

Airless lotion pumps can also contribute to sustainability efforts by reducing product waste due to their efficient dispensing and preservation capabilities. This helps minimize the need for excessive packaging and reduces the overall environmental impact.

“Airless pumps are a game-changer in the beauty industry,” says Dr. Emily Carter, a cosmetic chemist. “They provide superior protection for sensitive formulations, extending their shelf life and ensuring consumer safety.”

Airless Lotion Pump Applications Beyond Skincare

While widely used in skincare, the benefits of airless lotion pumps extend to other applications:

- Pharmaceutical Products: Maintaining the sterility and potency of medications.

- Hair Care Products: Protecting delicate hair serums and treatments.

- Makeup Products: Dispensing liquid foundations and concealers hygienically.

- Paint and Coatings: Delivering consistent and controlled application.

“The versatility of airless pumps is truly impressive,” adds John Miller, a packaging engineer. “Their ability to preserve and dispense a wide range of products makes them an invaluable asset across various industries.”

Airless Pumps Used in Various Products

Airless Pumps Used in Various Products

Conclusion

Airless lotion pumps offer a superior and innovative solution for dispensing a wide range of products. By protecting product integrity, enhancing hygiene, and promoting sustainability, airless lotion pumps are transforming the way we experience and interact with our favorite products. If you’re seeking a more effective and hygienic packaging solution, consider incorporating airless lotion pumps into your product line.

FAQ

- How do I refill an airless lotion pump?

- Are airless lotion pumps recyclable?

- What types of products are suitable for airless lotion pumps?

- How do I clean an airless lotion pump?

- What are the different types of airless lotion pump actuators?

- How do I choose the right size airless lotion pump for my container?

- Are airless lotion pumps more expensive than traditional pumps?

For any assistance, please contact us at Email: [email protected], or visit our office located at Fifth Avenue, 34th Floor, New York, NY 10118, USA. We have a 24/7 customer service team.